In industries where equipment downtime can lead to significant financial losses and operational disruptions, implementing predictive maintenance is crucial. For businesses in Libya, where operational efficiency is key to staying competitive, predictive maintenance significantly reduces costs, extends equipment lifespan, and boosts productivity.

Predictive maintenance leverages real-time data, sensors, and machine learning to forecast equipment failure, allowing businesses to perform maintenance just in time, optimising asset use and preventing unnecessary downtime. This approach is particularly valuable in Libya’s critical sectors such as oil and gas, manufacturing, transportation, and utilities, where uninterrupted operations are essential.

Qabas, the official Oracle™ partner in Libya, offers advanced Oracle Predictive Maintenance solutions tailored to the specific challenges faced by Libyan businesses, helping them ensure operational continuity and efficiency through data-driven insights.

Table of Contents

The Importance of Predictive Maintenance

In industries where operational efficiency directly impacts profitability, the need for a maintenance strategy that can minimise unplanned downtime, reduce repair costs, and ensure the reliability of critical equipment is paramount. This is especially true for Libyan businesses operating in sectors such as oil and gas, telecommunications, manufacturing, and government services, where any disruption in operations can have far-reaching economic consequences.

- Reduced Unplanned Downtime: By predicting when a piece of equipment is likely to fail, businesses can perform maintenance before a breakdown occurs, minimising costly interruptions to production or services.

- Lower Maintenance Costs: Traditional maintenance strategies often lead to over-servicing or under-servicing equipment. Predictive maintenance optimises the servicing schedule, ensuring that maintenance is only performed when absolutely necessary, reducing labour and material costs.

- Increased Equipment Lifespan: By maintaining equipment only when needed, predictive maintenance reduces wear and tear caused by over-maintenance, thereby extending the useful life of critical assets.

- Improved Safety and Compliance: Predictive maintenance helps ensure that equipment is operating within safe parameters, reducing the likelihood of accidents or malfunctions that could pose safety risks. Additionally, this strategy helps businesses comply with local regulations regarding equipment performance and maintenance standards, particularly in heavily regulated sectors like oil and gas.

- Enhanced Operational Efficiency: By integrating predictive maintenance with other business processes, companies can optimise inventory management for spare parts, reduce lead times for repairs, and ensure continuous operations, all of which contribute to greater efficiency and profitability.

For Libyan industries, these benefits are amplified by the challenges of operating in regions with infrastructure limitations, fluctuating fuel costs, and a growing need to comply with both local regulations and international standards.

Leveraging Predictive Maintenance: Why Oracle?

As the official Oracle™ partner in Libya, Qabas provides Oracle’s advanced Predictive Maintenance solutions, empowering Libyan businesses to optimise their maintenance processes through data analytics, machine learning, and Internet of Things (IoT) technology. Oracle’s predictive maintenance platform integrates seamlessly with existing enterprise resource planning (ERP) systems, providing a holistic view of equipment health, enabling real-time monitoring, and delivering actionable insights.

Key Features of Oracle Predictive Maintenance:

- Real-Time Equipment Monitoring with IoT Sensors

Oracle’s predictive maintenance platform uses IoT-enabled sensors to collect real-time data on the performance of equipment. These sensors measure key parameters such as temperature, pressure, vibration, and operational speed, which are fed into Oracle’s analytics engine for continuous monitoring. This allows businesses to gain a detailed understanding of how equipment is functioning at any given moment and to detect anomalies before they lead to a failure. - Machine Learning for Predictive Insights

By leveraging machine learning algorithms, Oracle’s platform analyses historical performance data to identify patterns and predict when equipment is likely to fail. This predictive capability allows businesses to schedule maintenance just in time, reducing unnecessary servicing while ensuring that critical equipment is maintained at optimal performance levels. - Integrated with Enterprise Resource Planning (ERP) Systems

Oracle’s predictive maintenance solutions are fully integrated with its ERP systems, enabling businesses to synchronise their maintenance schedules with inventory management, procurement, and asset management. This integration ensures that businesses have the necessary spare parts on hand, can efficiently allocate maintenance resources, and can track maintenance costs in real time. - Automated Maintenance Scheduling

Oracle Predictive Maintenance includes automated scheduling tools that ensure maintenance is performed at the optimal time. This system automatically adjusts maintenance schedules based on real-time data, ensuring that businesses avoid both unnecessary maintenance and unexpected equipment failures. - Data-Driven Decision Making

Oracle’s advanced data analytics capabilities allow businesses to gain deep insights into their maintenance processes. By generating reports on equipment performance, maintenance history, and operational efficiency, businesses can make informed decisions that improve their maintenance strategies and reduce overall operational costs. - Regulatory Compliance and Safety Assurance

Oracle’s predictive maintenance platform helps businesses ensure that they remain compliant with Libyan regulations and international standards by maintaining a comprehensive record of equipment performance and maintenance activities. This is especially important in sectors like oil and gas, where compliance with safety and environmental regulations is critical.

Tailored Predictive Maintenance Solutions for the Libyan Market

At Qabas, we understand the unique challenges that Libyan businesses face in managing and maintaining critical equipment. From infrastructure limitations to variable fuel costs and regulatory requirements, Libyan industries must navigate a range of operational hurdles. Our Oracle Predictive Maintenance solutions are designed to address these challenges, ensuring that your business can operate efficiently, reduce downtime, and optimise asset performance.

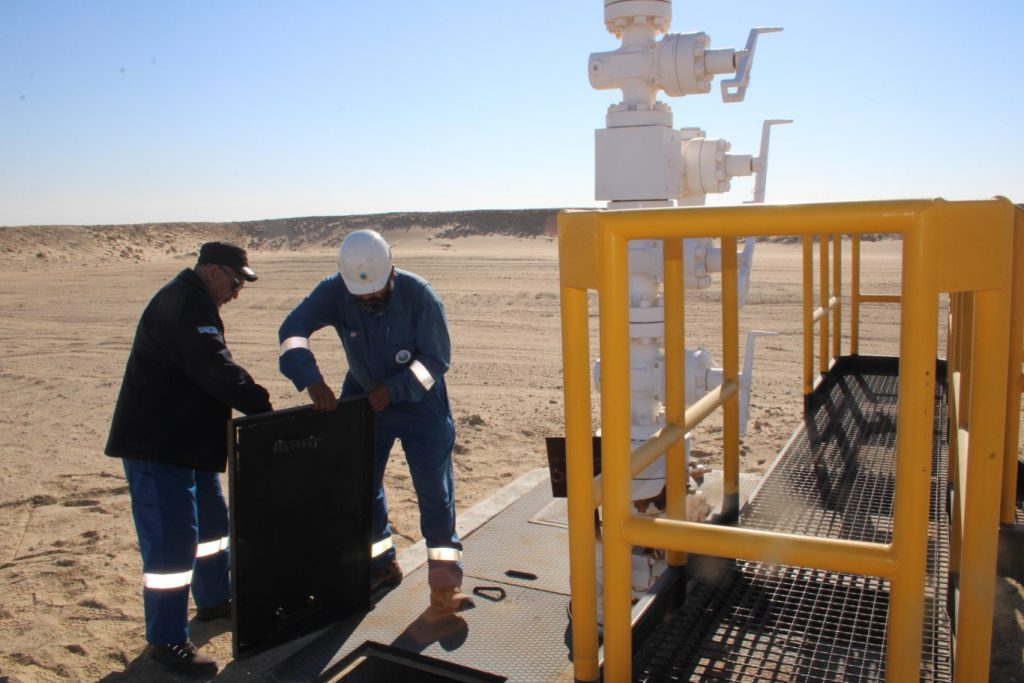

- Oil and Gas: Ensuring Equipment Reliability in Critical Operations

Libya’s oil and gas industry relies on a vast network of equipment, from drilling rigs to refinery machinery. Oracle’s Predictive Maintenance solution helps oil and gas companies monitor equipment performance in real time, predict failures, and schedule maintenance to ensure uninterrupted operations, while also complying with strict safety and environmental regulations. - Manufacturing: Optimising Production Line Efficiency

For manufacturers in Libya, equipment breakdowns can lead to costly production delays. Oracle’s Predictive Maintenance solution helps manufacturers monitor their machinery and production lines, predict when failures are likely to occur, and schedule maintenance during planned downtimes. This ensures that production targets are met without compromising on equipment health or operational efficiency. - Telecommunications: Maintaining Critical Network Infrastructure

Telecommunications providers in Libya manage a complex infrastructure of towers, servers, and network equipment. Oracle’s Predictive Maintenance helps telecom companies monitor their critical infrastructure, ensuring that network equipment operates at peak performance and that any potential issues are addressed before they result in service disruptions. - Government and Public Sector: Ensuring Infrastructure Reliability

Government entities in Libya that manage public infrastructure—such as power plants, transportation networks, and public utilities—rely on Oracle’s Predictive Maintenance solutions to keep these critical systems running smoothly. By predicting when maintenance is needed, public sector organisations can avoid costly breakdowns and improve service delivery. - Transportation and Logistics: Reducing Fleet Downtime

For businesses that manage large fleets of vehicles and transportation equipment, predictive maintenance is essential for reducing downtime and ensuring that goods are delivered on schedule. Oracle’s Predictive Maintenance solution allows transportation and logistics companies to monitor vehicle health, predict when maintenance is needed, and schedule repairs to minimise disruption to operations.

Why Partner with Qabas?

As the leaders in Oracle Predictive Maintenance implementation in Libya, Qabas offers unparalleled expertise in helping businesses leverage data-driven maintenance strategies. We combine global technology with a deep understanding of the Libyan operational landscape, ensuring that every solution is tailored to meet the specific needs of Libyan industries.

Our key strenghts include:

- Local Expertise, Global Technology: Qabas understands the unique challenges of operating in Libya’s business environment, from infrastructure limitations to the need for compliance with local regulations. By combining this local knowledge with Oracle’s world-class predictive maintenance technology, we deliver solutions that are both practical and effective in the Libyan context.

- End-to-End Predictive Maintenance Solutions: We provide a comprehensive approach to predictive maintenance, covering everything from equipment monitoring and data analytics to automated maintenance scheduling and regulatory compliance. Whether you operate in the oil and gas sector, manufacturing, or telecommunications, our solutions are designed to optimise your operations and reduce costs.

- Customised Solutions for Libyan Industries: Every business has different needs when it comes to predictive maintenance. Qabas ensures that our Oracle solutions are customised to meet the specific operational and regulatory challenges of your industry, ensuring that your maintenance strategy aligns with your business goals.

- Comprehensive Support from Implementation to Optimisation: From the initial deployment of your predictive maintenance system to ongoing data analysis and system optimisation, Qabas provides comprehensive support to ensure that your business continues to benefit from data-driven maintenance strategies that improve performance and reduce costs.

Take the Next Step with Qabas

Whether your business is looking to reduce equipment downtime, optimise maintenance costs, or improve operational efficiency, Qabas is your trusted partner for predictive maintenance solutions in Libya. As the #1 provider of Oracle Predictive Maintenance technology in the country, we are committed to helping your business achieve long-term success through data-driven asset management.

Contact Us Today

Ready to optimise your maintenance strategy? Contact Qabas today to schedule a consultation and discover how our tailored predictive maintenance solutions can support your business goals.